Instrumentation and Piping Accessories: Essential Components for a Complete Measurement System

The implementation of a precise and reliable flow measurement solution extends far beyond the primary flow element itself. It requires a fully integrated system where dedicated instrumentation and piping accessories are critical to ensuring measurement integrity, accuracy, and maintainability.

A professionally engineered system typically incorporates several key accessory categories:

1. Isolation and Connection Components

These provide the mechanical foundation and maintenance interface. Isolation Valves enable the safe shutdown of process fluid for maintenance or calibration. Mating Flanges and fasteners ensure a secure, leak-tight connection between the primary element and the existing process piping, meeting the required pressure class and standards.

2. Flow Conditioning Components

To guarantee a stable and symmetric flow profile at the meter inlet—a prerequisite for high accuracy—Flow Conditioners (Straighteners) are installed upstream. They eliminate swirl and asymmetric velocity profiles caused by elbows, valves, or other fittings.

3. Measurement Assurance and Signal Acquisition Components

These accessories directly facilitate safe and accurate signal transmission. For steam or hot gas applications, Condensate Pots (Seal Pots) protect the transmitter by maintaining equal liquid columns in impulse lines. The Manifold Valve (3-valve or 5-valve) is a core unit for differential pressure systems, allowing for transmitter isolation, equalization, and venting without process shutdown. Ultimately, the Pressure or Differential Pressure Transmitter converts the physical measurement into a standardized electrical signal.

In summary, the correct selection and integration of these accessories with the primary flow meter are fundamental to forming a reliable, accurate, and maintainable measurement solution, directly impacting the system’s long-term performance and total cost of ownership.

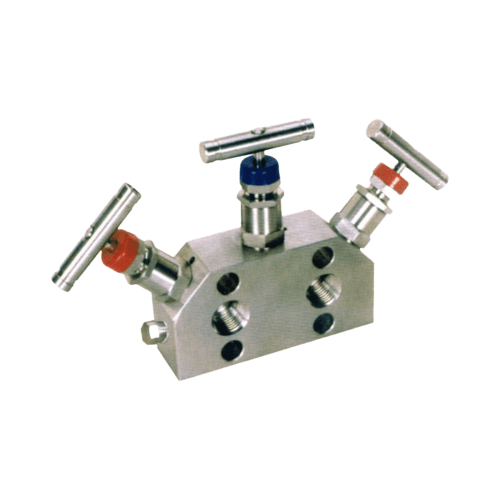

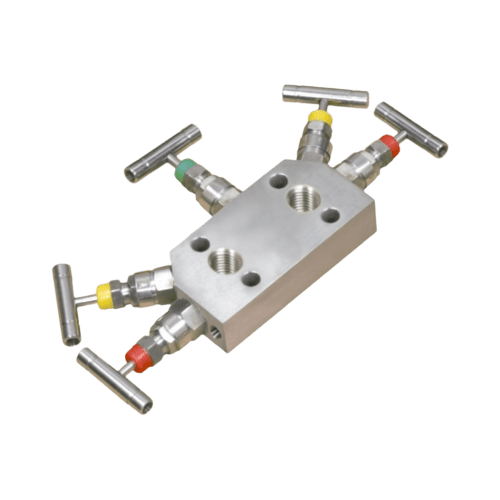

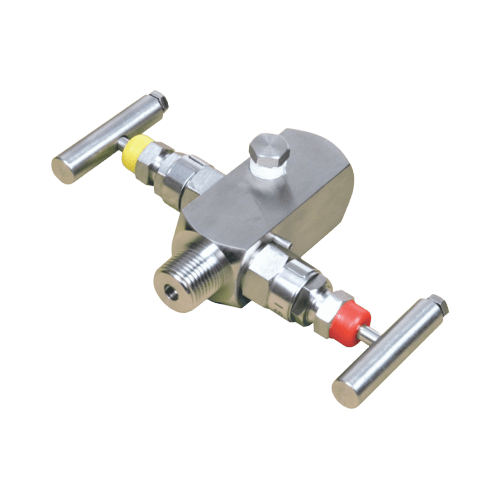

Instrumentation Manifold: A Configurable Interface for Measurement Integrity and Safety

An instrumentation manifold is a precision-engineered multi-valve assembly that serves as the critical interface between process pressure taps and a transmitter. Its primary functions are to ensure operational safety, facilitate calibration, and maintain signal integrity in differential pressure (DP) measurement systems.

Core Functions & Configurations:

The manifold’s value is realized through three core operations: Isolation (safely disconnecting the transmitter from live process pressure), Equalization (balancing pressures across the transmitter to establish a true zero point for calibration), and Venting/Purging (clearing impulse lines of unwanted gas or liquid).

These functions are implemented through standardized valve configurations, each suited to specific application needs:

- 2-Valve Manifold: Provides basic high-pressure (HP) and low-pressure (LP) line isolation. It allows the transmitter to be isolated but lacks a dedicated equalization valve, making it suitable for simple on/off service or gauge pressure applications where in-line zero calibration is not required.

- 3-Valve Manifold: The standard for most DP flow or level applications. It integrates two block valves (HP, LP) and one central equalizing valve. This configuration enables safe isolation and precise in-line zero calibration without process shutdown, which is fundamental for maintaining accuracy.

- 5-Valve Manifold: Builds upon the 3-valve design by adding two separate vent/bleed valves (one on each leg). This allows for advanced diagnostics, such as isolating and testing individual impulse lines, performing safe overpressure protection checks, and venting trapped air or draining condensate from each line independently. It is essential for critical, high-accuracy, or diagnostic-intensive applications, particularly with wet legs or challenging fluids.

High-Performance Instrumentation Fittings for Critical Process Connections

Instrumentation fittings are fundamental components engineered to ensure the integrity, safety, and reliability of process measurement and analytical tubing systems. Among the most robust designs are double ferrule compression fittings, which utilize a precision two-ring mechanism: the front ferrule creates a leak-tight seal against the tubing, while the rear ferrule provides superior grip and mechanical support, preventing pull-out and maintaining alignment.

This advanced design is specifically developed for securing leak-free connections in critical applications. It delivers exceptional performance under challenging conditions, including high-pressure and vacuum systems, environments with significant vibration, and services involving corrosive media. To certify their suitability for demanding energy sectors, such fittings often hold specific approvals like EC-79 for hydrogen service and ECE-R110 for natural gas systems.

Available in a comprehensive range of materials—including stainless steel, brass, duplex alloys, and exotic metals such as Hastelloy, Inconel, and Titanium—these fittings provide optimal material compatibility for virtually any process fluid, from ultrapure standards to highly aggressive chemicals.

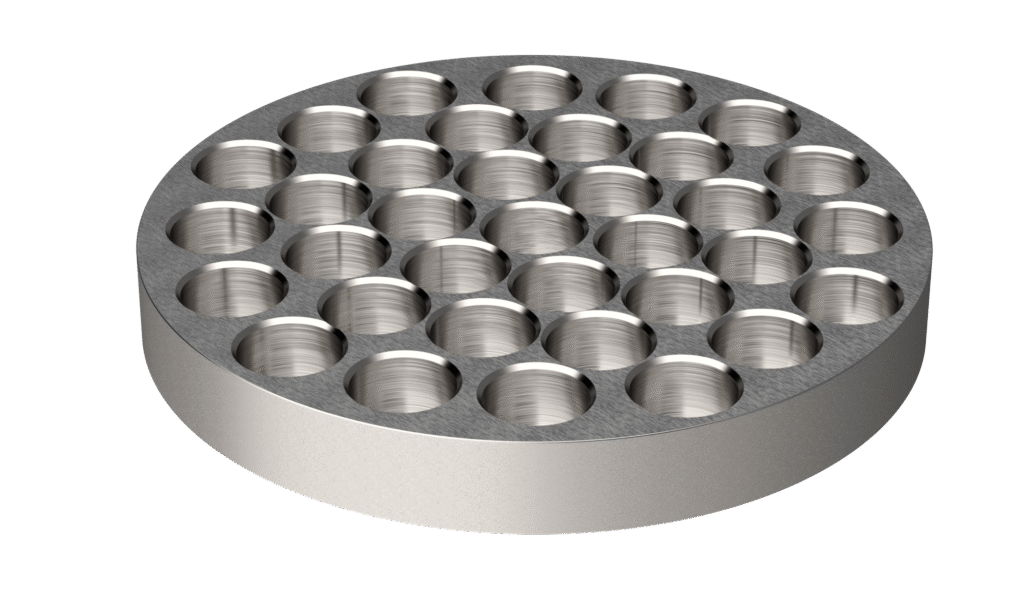

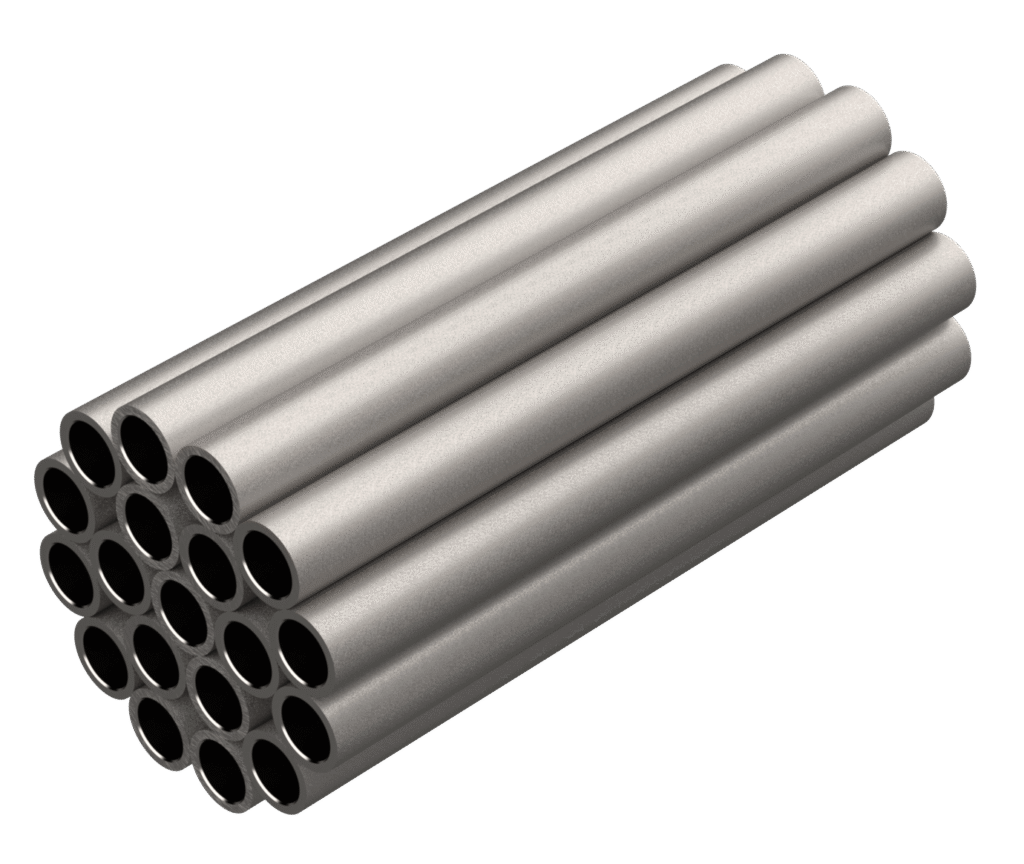

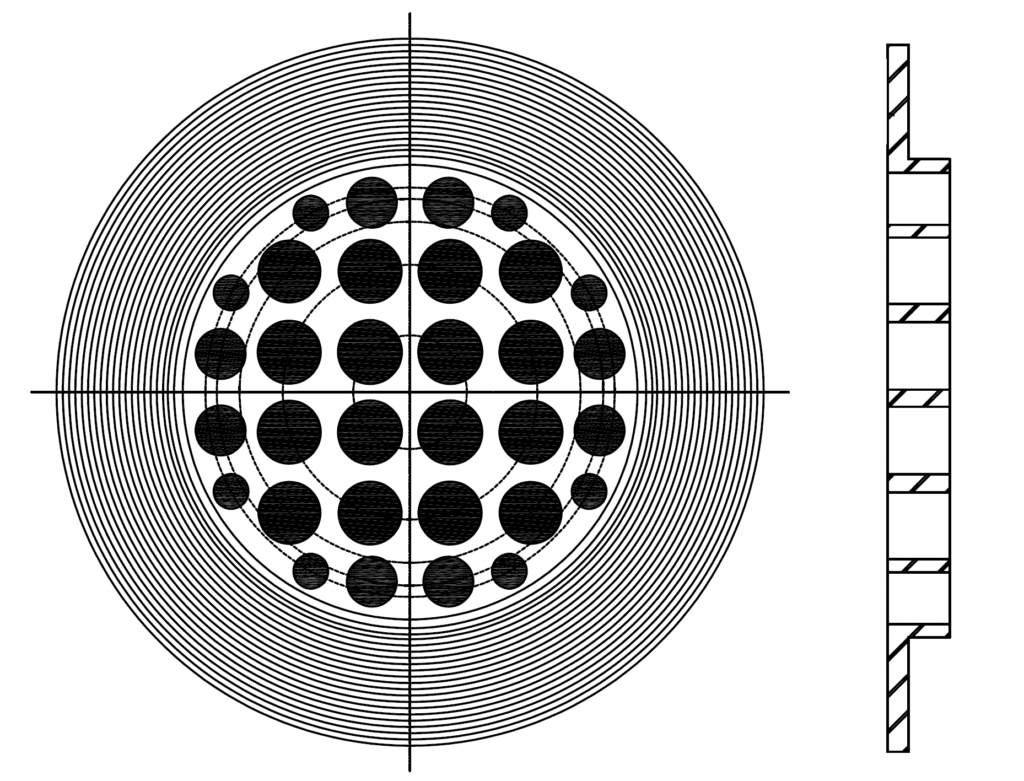

Flow Conditioners: Critical Components for Hydraulic Profile Stabilization

A flow conditioner is a precisely engineered passive device installed upstream of a flow meter to rectify and stabilize the fluid velocity profile entering the measurement section. Its fundamental purpose is to eliminate or significantly reduce flow distortions—such as swirl and asymmetric velocity distributions—that are caused by upstream pipe fittings (e.g., elbows, valves, reducers). By creating a fully developed, predictable, and symmetric flow profile, it ensures that the flow meter operates within its specified accuracy and repeatability parameters, which is a prerequisite for achieving certified measurement performance.

Primary Designs and Operating Principles

Different designs target specific flow disturbances:

Zanker (or AMCA) Profile Plate: A more sophisticated variant featuring a central hub and radiating vanes. It is specifically designed to eliminate swirl with minimal pressure loss. The vanes impart an opposite rotational momentum to cancel existing swirl.

Tube Bundle (Perry/AGA) Conditioner: Consists of a bundle of small, parallel tubes. It effectively breaks up large-scale swirl by subdividing the flow into numerous small channels and dampens asymmetric profiles through flow resistance and mixing at the tube exits. It offers a good balance between conditioning performance and permanent pressure loss.

Perforated Plate Conditioner: A plate with a specific pattern of holes. It acts as a flow “straightener” and homogenizer by imposing a high, uniform resistance across the pipe cross-section, thereby smoothing out velocity variations. Its simplicity is an advantage, but it typically generates a higher pressure drop than tube bundles.

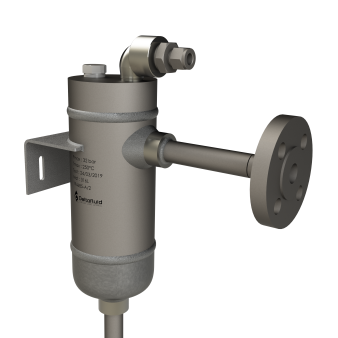

Condensing Chamber Unit: An Integral Protection Element for Reliable Differential Pressure Measurement

A condensate pot, also known as a seal pot, is a critical auxiliary vessel engineered to ensure the accurate and reliable operation of differential pressure transmitters in demanding process conditions. Its primary function is to provide both thermal safeguarding and hydraulic stability within the measurement impulse lines.

In steam or hot gas service, the pot is installed in each impulse line, allowing the live steam to condense within it. This creates and maintains a constant-height column of condensate above the transmitter’s sensing diaphragms. This barrier effectively protects the transmitter from damaging process temperatures while establishing a stable, reproducible reference for precise differential pressure measurement.

Beyond thermal protection, this principle is extended to corrosive or aggressive fluids. When filled with a compatible isolation fluid, the pot acts as a chemical separation barrier, preventing the process medium from contacting and corroding the transmitter. In this configuration, it is accurately termed a separation pot.

Thus, by mitigating the two primary threats to transmitter integrity—extreme heat and chemical attack—the condensate/separation pot is fundamental to maintaining long-term measurement accuracy and protecting critical instrumentation assets.