Optimized & Industry-ready Solutions

For All Your Complicated Needs

Nozzle Flow Meters: Robust Measurement for Demanding Applications

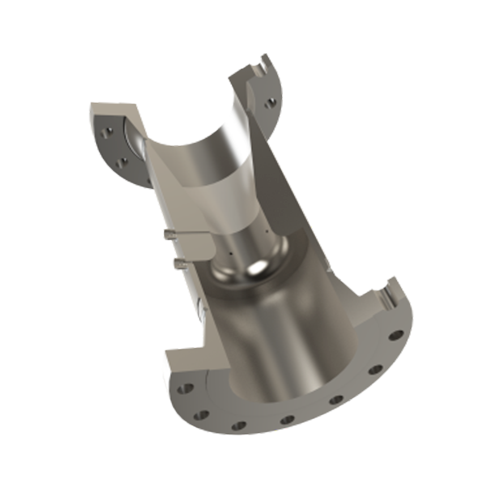

Engineered for reliable performance in challenging fluid conditions, the nozzle flow meter is characterized by a smoothly contoured, convergent inlet profile. This hydrodynamic design minimizes turbulence and energy loss, making it particularly suitable for high-velocity fluid streams.

Unlike an orifice plate, whose sharp upstream edge is susceptible to wear and damage, nozzle designs such as the ISA 1932 Nozzle and the Long Radius Nozzle (as defined by ISO 5167 or ASME MFC-3M standards) offer superior durability. Their robust, rounded inlet geometry provides excellent resistance to erosion, ensuring long-term measurement stability in demanding applications.

To further enhance service life in corrosive or aggressive fluid service, the internal wetted surfaces can be protected with specialized protective coatings or manufactured from corrosion-resistant alloys. This adaptability makes the nozzle a versatile and resilient choice for accurate differential pressure flow measurement in severe operating environments.

Features

Accuracy: ±1.0% of rate, ±0.5% of rate, ±0.25% of rate

Body material: Duplex 2205, 304, or 316 stainless steel, Hastelloy C-276, 254, SMO, carbon steels; Special materials on request.

Calibration: Calibrated for customer application

Fitting Type: Flanged, threaded, hub or weld-end standard; Others on request.

Head Loss: The permanent pressure loss is between 10% and 20% of DP

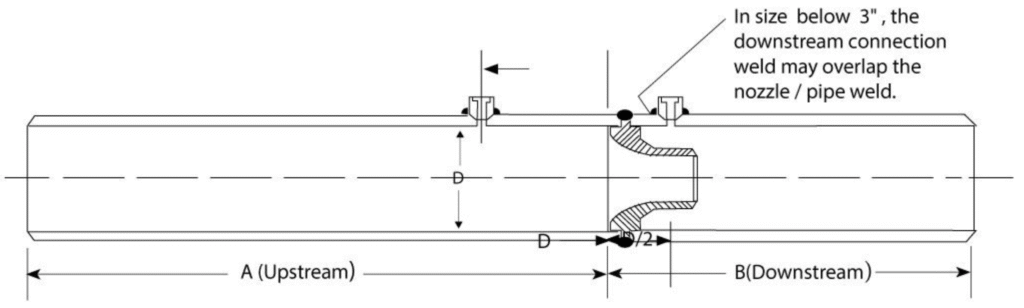

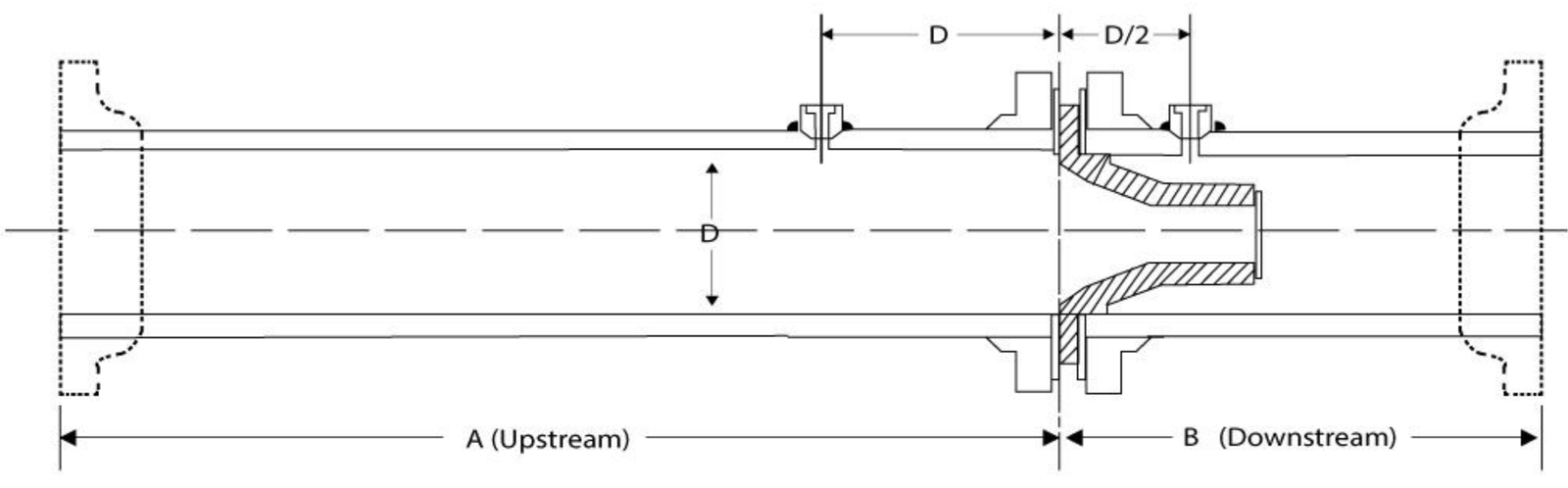

Installation Requirement: Comply with the ISO 5167 standard.

Line size: 0.5 to 180″ or larger

Pressure Range: Up to 20,000 psi (1,380 bar)

Repeatability: ±0.1%

Standard Beta Ratios: 0.30 to 0.75, special betas available

Temperature Range:up to 1,600 °F (870°C)