Optimized & Industry-ready Solutions

For All Your Complicated Needs

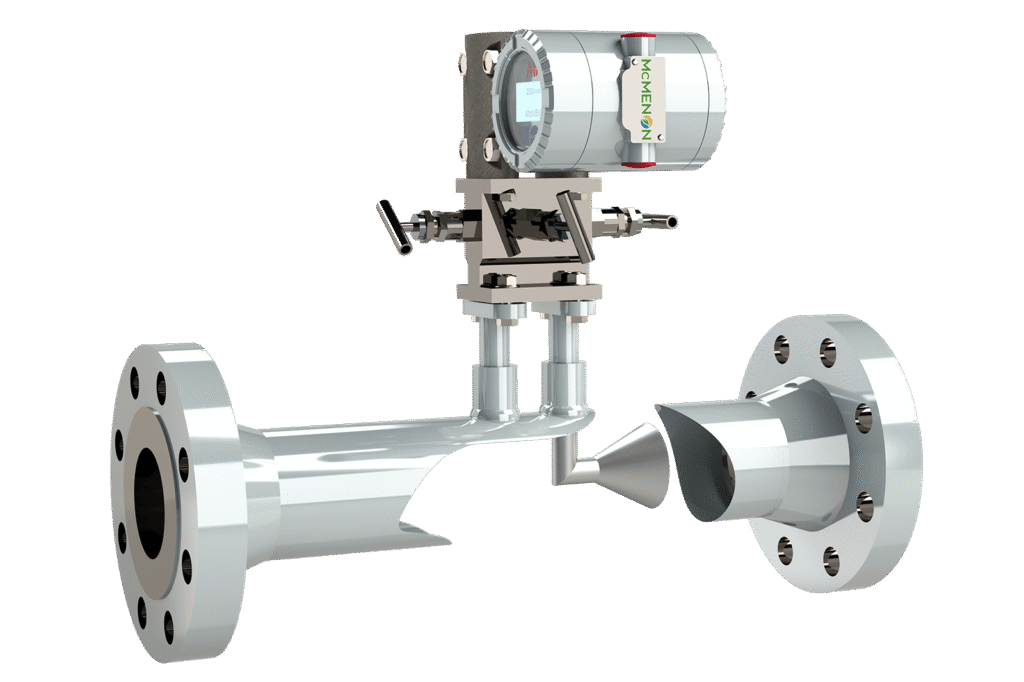

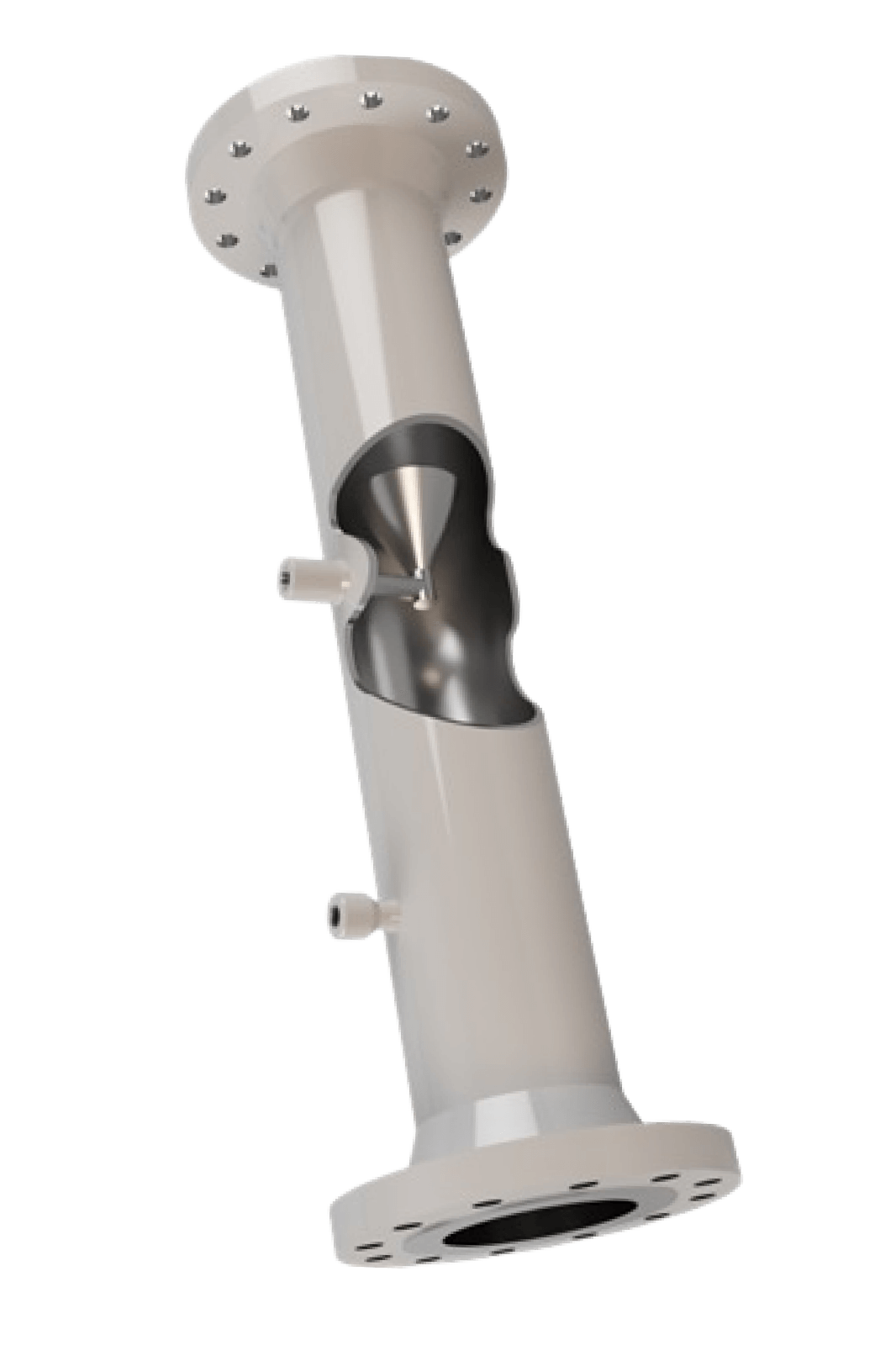

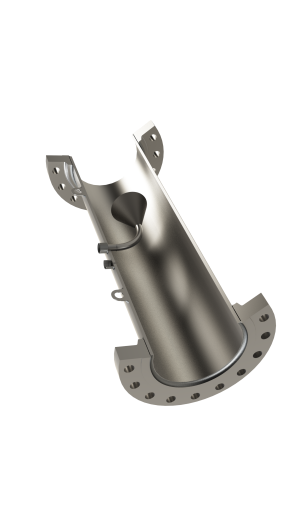

Cone Flow Meter: A Differential Pressure Device with Advanced Flow Conditioning

The cone flow meter is a differential pressure-based primary element distinguished by its centrally mounted, conical obstruction. This design creates an annular restriction that accelerates the fluid, generating a controlled low-pressure region downstream of the cone, as described by Bernoulli’s principle. The measured differential pressure between the upstream static tap and this low-pressure zone is used to calculate flow rate.

Its core advantage lies in the cone’s flow-conditioning effect. The symmetrical design reshapes and centralizes the velocity profile, drastically reducing dependency on upstream straight pipe runs (often to 0-3 diameters) and minimizing measurement uncertainty from swirl or asymmetric flows. This makes it exceptionally robust for challenging applications involving dirty, viscous, or multiphase fluids, where it resists fouling and maintains long-term accuracy and repeatability.

Features

Accuracy: ±1.0% of rate, ±0.5% of rate

Body material: Duplex 2205, 304, or 316 stainless steel, Hastelloy C-276, 254, SMO, carbon steels; Special materials on request.

Calibration: Calibrated for customer application

Fitting Type: Flanged, threaded, hub or weld-end standard; Others on request.

Head Loss: The permanent pressure loss is between 10% and 20% of DP

Installation Requirement: Comply with ISO 5167-1 & 5 or R.W. MILLER.

Line size: 0.5 to 60″ or larger

Pressure Range: Up to 20,000 psi (1,380 bar)

Repeatability: ±0.1%

Standard Beta Ratios: 0.30 to 0.75, special betas available

Temperature Range:up to 1,600 °F (870°C)

Bi-directional measurement possible.