Optimized & Industry-ready Solutions

For All Your Complicated Needs

Rectangular Flow Meter: A Differential Pressure Solution for Challenging Fluids

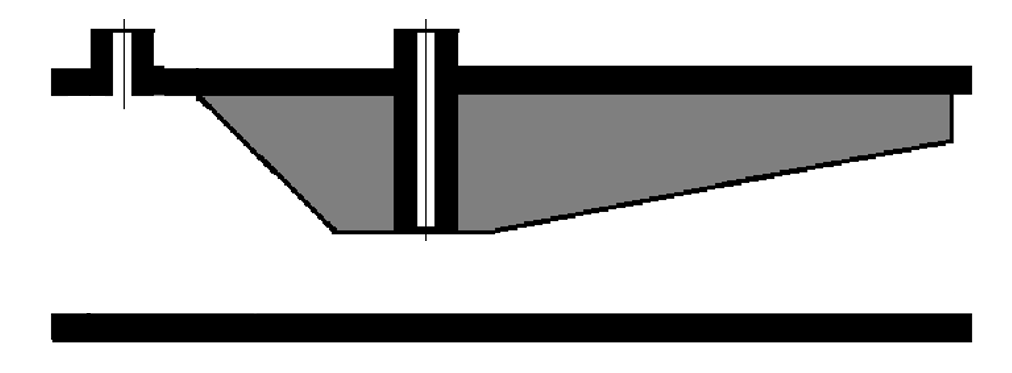

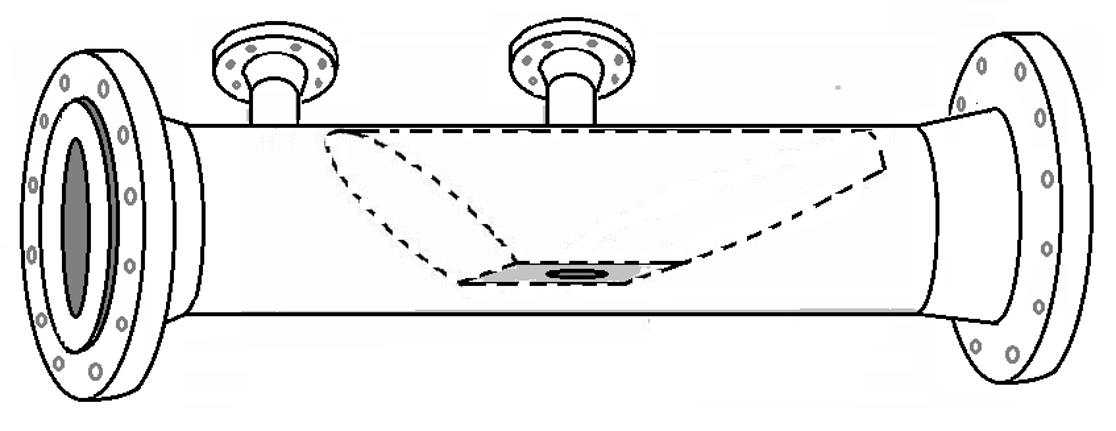

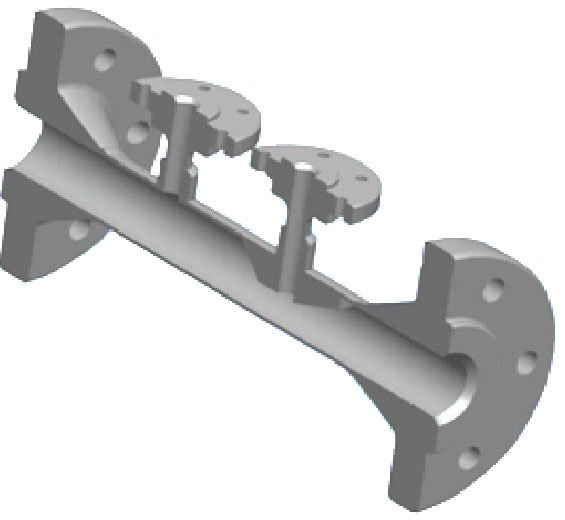

The Rectangular Flow Meter is a differential pressure-based flow measurement device distinguished by its unique rectangular orifice or flow conditioning element. This design is engineered to deliver accurate and reliable measurement across a broad spectrum of media, including gases, steam, and liquids—even those with challenging properties such as high viscosity (e.g., oils, slurries), high abrasiveness (containing solid particles), and high corrosivity.

Key Technical Advantages:

Superior Performance with Complex Fluids: Its optimized flow geometry ensures stable signal generation and minimal susceptibility to fouling, making it particularly effective where conventional meters fail.

High Accuracy & Wide Turndown: The device maintains high measurement accuracy over an extensive flow range.

Low Permanent Pressure Loss: The efficient design results in a significantly reduced head loss, typically only 30% to 50% of that incurred by wedge-type flow meters, leading to substantial energy savings in pumped systems.

Installation Flexibility: The primary element can be installed in both square and circular pipes, offering great adaptability for retrofit projects.

Reliability and Durability:

Constructed with no moving parts, the meter is highly resistant to wear and degradation caused by abrasive or corrosive flows. This robust construction ensures that its initial measurement precision is maintained over the long term, a critical advantage over technologies like orifice plates, wedge meters, or turbine meters that are prone to drift or damage under harsh conditions.

In summary, the Rectangular Flow Meter provides a robust and precise solution for the long-term measurement of difficult process fluids, effectively addressing long-standing industry challenges in achieving reliable and accurate flow data for viscous, corrosive, and abrasive media.