Optimized & Industry-ready Solutions

For All Your Complicated Needs

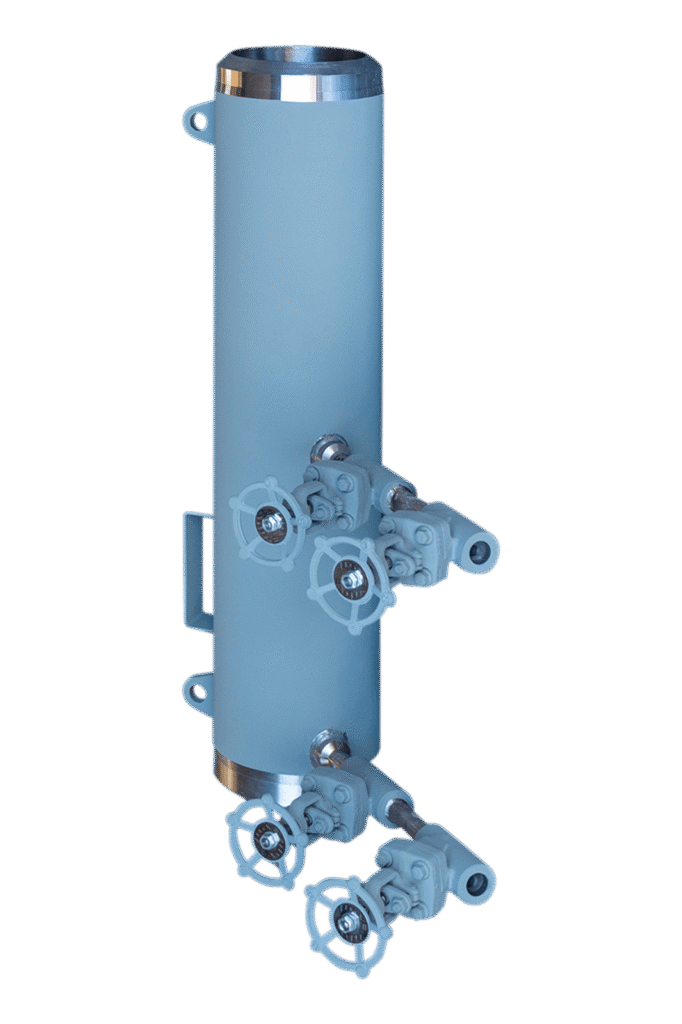

The Venturi Tube: Efficient Differential Pressure Flow Measurement

The Venturi tube is a classical differential pressure flow meter characterized by its three distinct sections: a convergent inlet, a constricted throat, and a gradual divergent outlet. This design is renowned for generating a highly repeatable differential pressure signal while maintaining a low permanent pressure loss, making it exceptionally efficient for measuring flows, including low-pressure systems. A further practical advantage is its requirement for minimal upstream and downstream straight pipe runs.

To suit various applications and sizes, Venturi tubes are manufactured in key types:

Machined Venturi: Fabricated from solid round stock, offering precision for smaller line sizes.

Rolled Welded Venturi: Constructed from sheet metal, providing a cost-effective solution for larger diameters, typically up to 1200 mm.

“As-Cast” Venturi: Produced via foundry casting for superior internal profile accuracy and hydraulic performance, commonly available up to 800 mm diameter.

This combination of efficiency, compact installation footprint, and versatile construction makes the Venturi tube a reliable choice for demanding flow measurement.

Features

Accuracy: ±1.0% of rate, ±0.5% of rate, ±0.25% of rate

Body material: Duplex 2205, 304, or 316 stainless steel, Hastelloy C-276, 254, SMO, carbon steels; Special materials on request.

Calibration: Calibrated for customer application

Fitting Type: Flanged, threaded, hub or weld-end standard; Others on request.

Head Loss: The permanent pressure loss is between 10% and 20% of DP

Installation Requirement: Comply with the ISO 5167 standard.

Line size: 0.5 to 180″ or larger

Pressure Range: Up to 20,000 psi (1,380 bar)

Repeatability: ±0.1%

Standard Beta Ratios: 0.30 to 0.75, special betas available

Temperature Range:up to 1,600 °F (870°C)