Optimized & Industry-ready Solutions

For All Your Complicated Needs

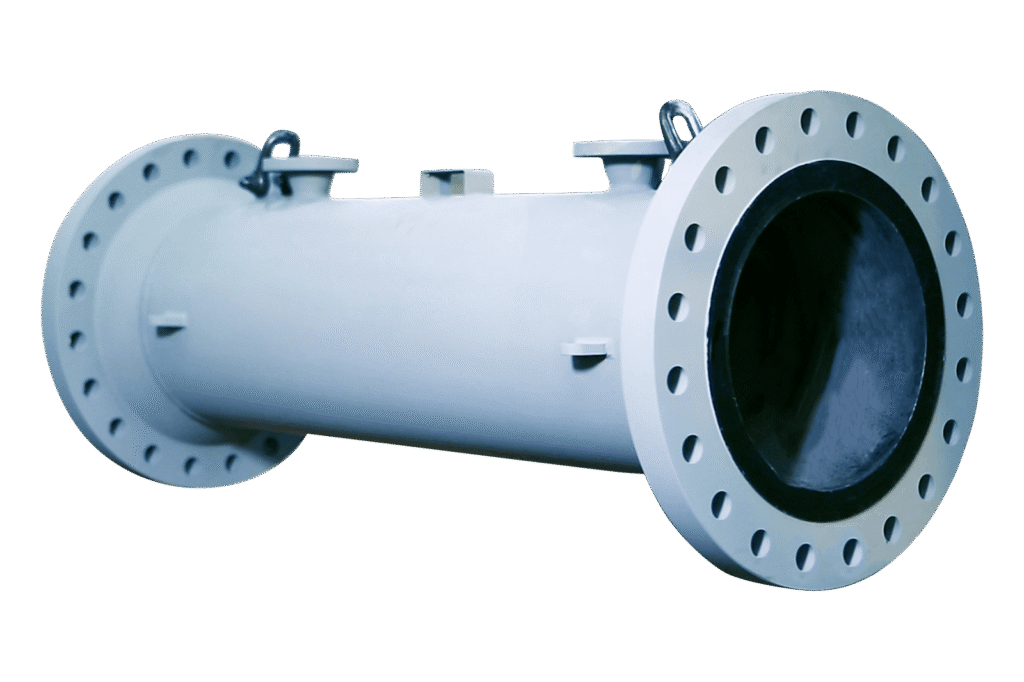

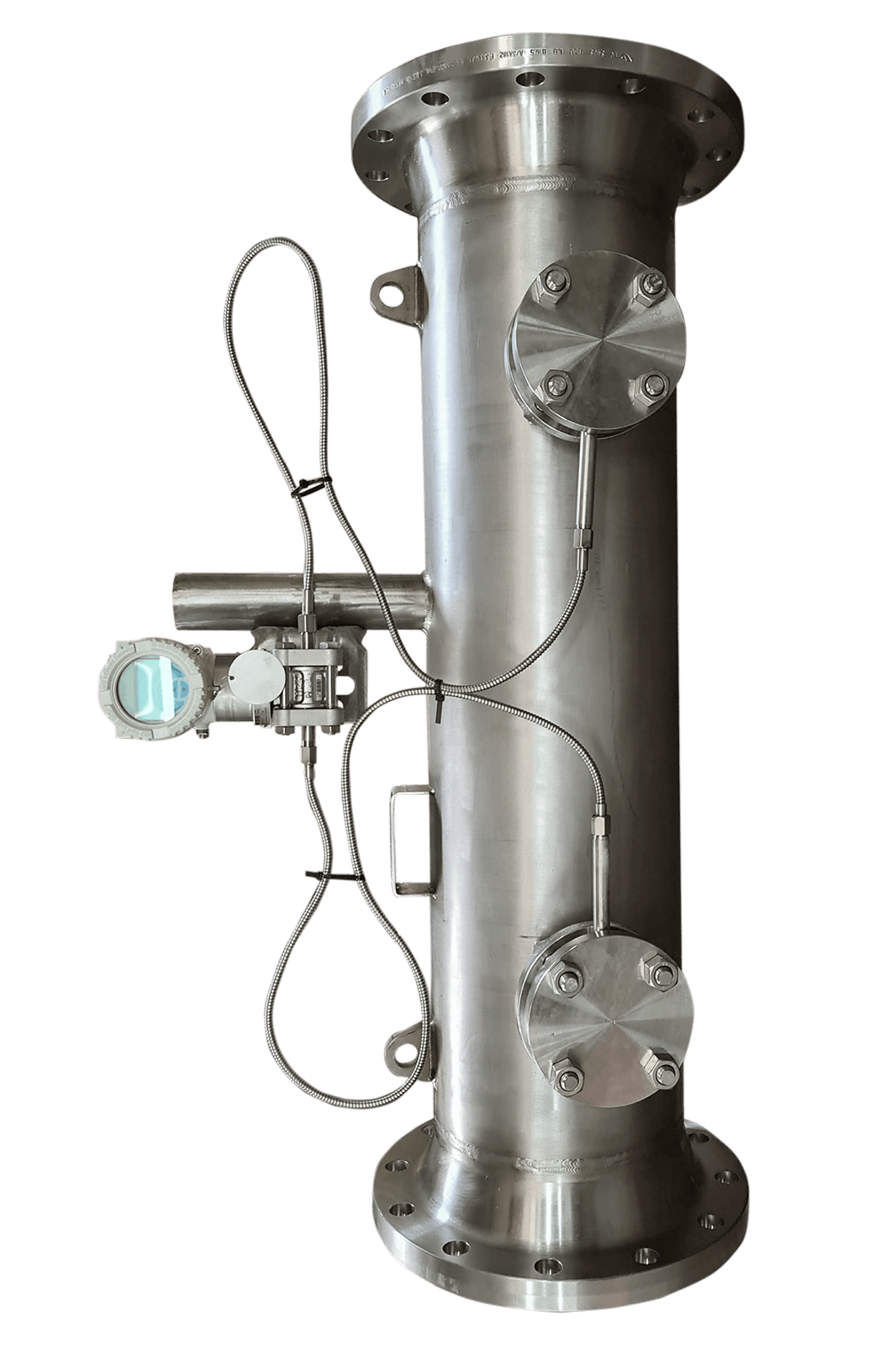

Wedge Meter: A Robust Differential Pressure Flow Solution for Demanding Applications

The wedge meter is a highly adaptable differential pressure-based flow measurement device designed to meet a wide range of process conditions and installation requirements. It is renowned for its durability and reliability in challenging environments.

Its primary strength lies in its exceptional handling of complex fluids. The meter’s unique V-shaped wedge element, which creates a constriction in the flow path, lacks sharp edges or dead zones. This design makes it particularly suitable for measuring dirty, viscous, abrasive, or fouling-prone fluids. It effectively resists wear that would typically damage the more sensitive measurement surfaces of other, less robust technologies, ensuring long-term measurement accuracy and service life.

In terms of performance, the wedge meter offers one of the widest turndown ratios among differential pressure flow devices, enabling accurate measurement across very low to very high flow rates. Furthermore, it requires shorter upstream and downstream straight pipe runs compared to many other primary differential pressure elements, providing significant advantages for retrofits or installations in space-constrained locations.

As a mature technology, wedge meter design and manufacturing are supported by established industry practice and standards, including adherence to modern international guidelines such as ISO 5167-6:2019. This ensures reliable and consistent performance, solidifying its position as a preferred solution for harsh industrial flow measurement challenges.

Features

Accuracy: ±1.0% of rate, ±0.5% of rate

Body material: Duplex 2205, 304, or 316 stainless steel, Hastelloy C-276, 254, SMO, carbon steels; Special materials on request.

Calibration: Calibrated for customer application

Fitting Type: Flanged, threaded, hub or weld-end standard; Others on request.

Head Loss: The permanent pressure loss is between 10% and 20% of DP

Installation Requirement: Comply with ISO 5167-1 & 6 or R.W. MILLER.

Line size: 0.5 to 60″ or larger

Pressure Range: Up to 20,000 psi (1,380 bar)

Repeatability: ±0.1%

Standard Beta Ratios: 0.30 to 0.75, special betas available

Temperature Range:up to 1,600 °F (870°C)

Bi-directional measurement possible.