Products

Professional Solutions for Industrial Temperature Measurement

Accurate and reliable temperature measurement is fundamental to process control, safety, and efficiency across industries. A range of specialized sensor technologies and installation methods are engineered to meet diverse application requirements, from standard in-pipe monitoring to complex vessel profiling.

1. In-Pipe Sensing: Direct Measurement with Engineered Protection

Direct immersion sensing provides the most accurate measurement of fluid temperature by minimizing thermal lag and environmental influence.

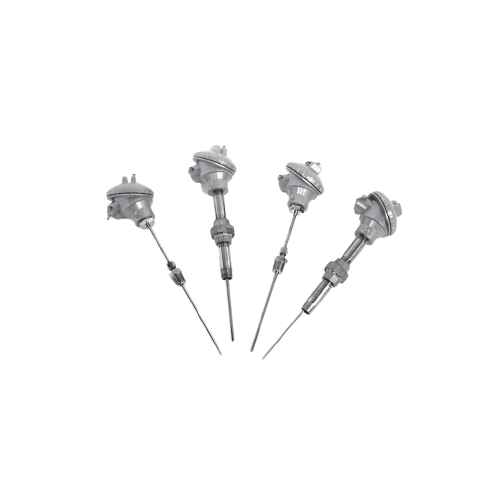

Hazardous Area Integration: Sensors and transmitters are certified for use in classified areas (e.g., ATEX, IECEx) with protection methods such as Intrinsic Safety (Ex ia) or Flameproof (Ex d) enclosures. Integral head-mounted transmitters enable 4-20mA HART/Foundation Fieldbus output, reducing signal noise and installation cost.

Sensing Technology & Selection:

Platinum Resistance Thermometers (PRTs/RTDs) offer superior accuracy, long-term stability, and linearity (e.g., Class A per IEC 60751), making them the preferred choice for precise control and custody transfer applications, typically within -200°C to 600°C ranges.

Thermocouples provide broader temperature ranges (up to 1700°C+ with Type B/R/S), faster response, and robust physical construction, but with slightly lower absolute accuracy and inherent drift over time. Selection is based on the Seebeck coefficient and material compatibility (e.g., Type K for general use, Type J for reducing atmospheres).

Installation & Safety Methodology:

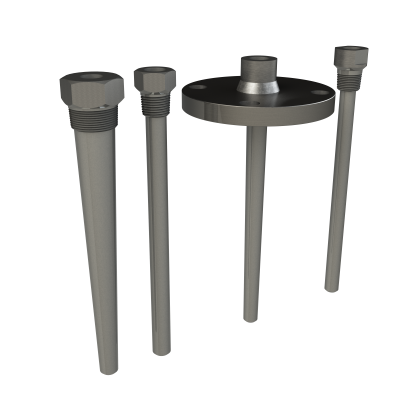

Thermowell Deployment: The standard for pressurized, continuous, or hazardous processes. Drilled barstock thermowells, machined per ASME PTC 19.3, are engineered for severe service. Their natural frequency is calculated to avoid resonant vibration-induced fatigue failure from vortex shedding at high flow velocities. Materials range from 316SS to high-nickel alloys (Inconel 625, Hastelloy C-276) for corrosion resistance.

Self-Sealing Coupling Systems: Provide a robust, pressure-rated (often via a gland seal) direct-insertion method where frequent sensor removal is required, eliminating the need for a separate shut-off valve. They are ideal for clean, non-hazardous services.

2. Surface Mount Sensors: Non-Invasive Measurement Strategy

Used when process penetration is prohibited or impractical, this method infers internal fluid temperature from the external pipe or vessel wall temperature.

Advanced Correction Algorithms: Smart transmitters can apply corrections based on pipe material, wall thickness, and insulation properties.

Performance Engineering: Accuracy is contingent upon minimizing thermal resistance. This is achieved through:

Optimal Sensor-to-Surface Contact: Using thermal conductive paste or epoxy and ensuring uniform clamping force.

Comprehensive, High-Efficiency Insulation: Encasing both the sensor and a significant length of pipe to establish an adiabatic zone, effectively making the pipe wall an extension of the sensor. When properly installed, measurement deviation from a true immersion probe can be limited to within 1-2°C for many applications.

3. Specialized Sensor Architectures for Complex Applications

Multipoint Sensors: Engineered for temperature profiling in large process vessels (e.g., catalytic reactors, fractionation columns, SCR systems). Multiple sensing elements (PRTs or T/Cs) are integrated at precisely specified intervals along a single rigid or flexible carrier, enabling measurement through a single vessel nozzle. Designs are highly customized based on insertion length, point spacing, pressure rating, and carrier material stiffness.

Cable Sensors: Utilize mineral-insulated, metal-sheathed (MIMS) cable construction, offering flexibility, high-temperature resilience (up to 1100°C), and environmental sealing. They are routed along vessel exteriors, inserted into protective thermowells with curved entries, or used in hard-to-reach locations. Terminations vary from simple connection heads to field-mounted transmitters.